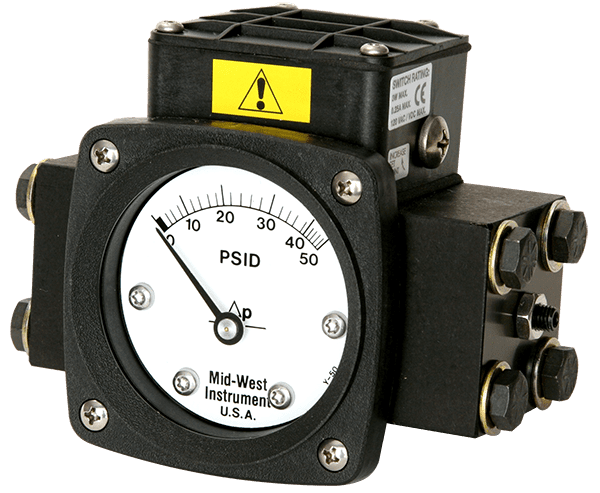

140

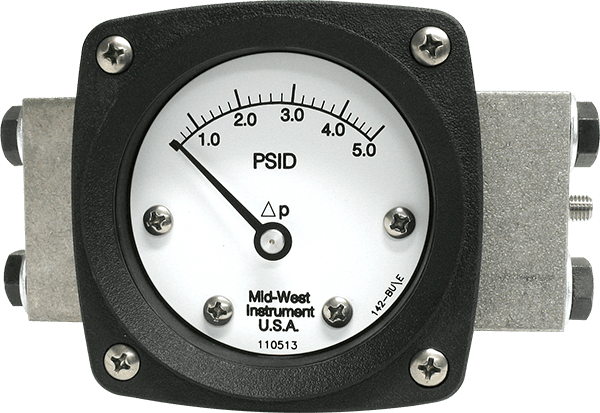

Diaphragm Type Gauges

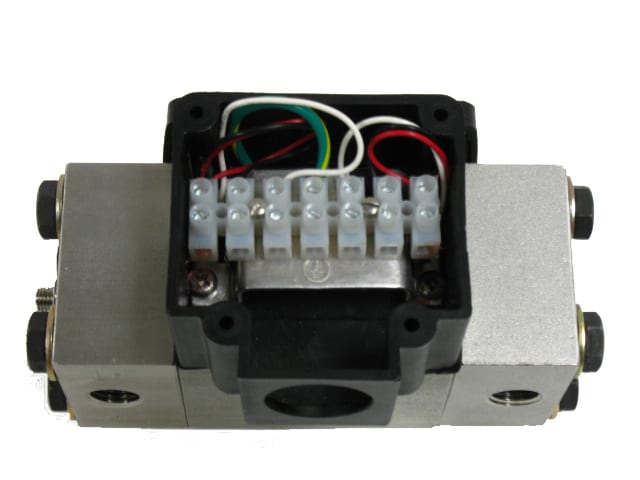

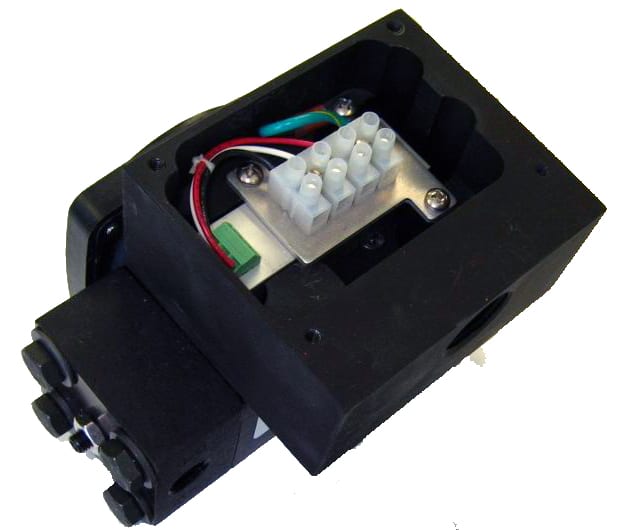

SPST, 25 Watts, 0.5 Amp, 230 VAC/VDC (normally open)

140-AA-00-OO

3000 P.S.I.G. working pressure, aluminum body, 316 Stainless Steel internal metal parts, Buna-N diaphragm and seals, Teflon®** guide bushings, ¼” FNPT back connections and engineered plastic gauge case

140-BA-00-OO

1500 P.S.I.G. working pressure, brass body, 316 Stainless Steel internal metal parts, Buna-N diaphragm and seals, Teflon®** guide bushings ¼” FNPT back connections and engineered plastic gauge case

140-SA-00-OO

3000 P.S.I.G. working pressure, 316/316L Stainless Steel body and internal metal parts, Buna-N diaphragm and seals, Teflon®** guide bushings, ¼” FNPT back connections and engineered plastic gauge case

Product Features and Benefits

- Total separation of high and low by a convoluted elastomer diaphragm

- Sensor magnetically coupled to the indicating pointer and optional switches

- Over-range protection to max pressure

- Weatherproof rated to NEMA 4X/IP65

- Dial: 2-1/2″ & 4-1/2″ Uni-Directional

- Operating Temp. -40º F to +200º F (-40ºC to +93ºC)

- Working Pressure: 3,000 PSI (Proof Pressure: 6,000 PSI) (Aluminum & Stainless Steel Bodies)

- Working Pressure: 1,500 PSI (Proof Pressure: 3,000 PSI) (Brass Body)

The Model 140/142 provides outstanding capabilities not previously available. It is ideally suited for use on dissimilar fluids, wet gas or fluids with high concentration of solids, etc. Use in, Filter/Strainer Monitoring, Compressed Air, Hydraulic, Refrigerant, Pump Performance Testing, Heat Exchanger Pressure Drop Monitoring, Water Treatment Applications, Tank Level Monitoring Horizontal or Vertical and Flow Monitoring & Balancing

Choose Aluminum, 316L Stainless Steel or Brass Body based on the process media your gauge comes into contact with.

About This Product

DP Range 140: 0-25 PSID (0-1.7 bar) thru 0-100 PSID (0-7 bar)

DP Range 142: 0-20 In H2O (0-50mbar) thru 0-25 PSID (0-1.7 bar)

Mid-West Diaphragm Type: Models 140 & 142 ± 2% Full Scale Accuracy. The high and low-pressure ports are completely isolated from each other. There is no bypass and therefore they are best suited for air or gas along with liquids. They also come in a variety of sizes allowing for very sensitive measurements. The Differential Pressure is sensed by the movement of an elastomer diaphragm against a precision calibrated range spring. The change in position of the diaphragm in response to the change in Differential Pressure moves an internal magnet. This magnet, in turn, causes a rotary magnet external to the gauge body to rotate. This rotary magnet has a pointer attached which indicates the differential pressure on the dial. The diaphragm provides total separation.

MODEL 140/142-COMMON OPTIONS:

DP Ranges: Inches H2O, PSID, Bar, and Kpa

Body Materials: Aluminum, Brass and 316L Stainless Steel

Dial Types: 2-1/2″ or 4-1/2″ round Uni-Directional

Seals & Diaphragm Materials: Buna-N, Viton

Carbon or Stainless Steel Pipe Mount Kits

Liquid Fill or Maximum Follower Pointer (Can not combine Liquid Fill with Maximum Follower Pointer options)

Wall Mount Kit (Wall Mount option not available for Model 142 with back connections)

Connections: 1/4″ or 1/2″ FNPT

FOR A QUOTE ON ADDITIONAL OPTIONS PLEASE CALL:

1-800-648-5778

MODEL 140/142-ADDITIONAL OPTIONS:

Dial Types: 4-1/2″ Round Uni-directional anodized aluminum housing assembly.

Non-Indication with select switch options.

Seals & Diaphragm Materials: Silicone, Neoprene(25 PSID & Up.) and Ethylene Propylene

Connections: 7/16″-20 Straight thread “O” ring port

Other Options: Reversed high/low process connections, Oxygen Cleaning, Stainless Steel Tags and more…

Standards

All Model 140/142 differential pressure gauges either conform to and/or are designed to the requirements of the following standards:

ASME B1.20.1

ASME B40.100

CSA-C22.2 No. 14.25 and 30

NACE MR0175

NEMA Std. No. 250

SAE J514

From: $0.00

The Mid-West Advantage

- 5 year warranty

- 30 + Years Hazardous Location product manufacturer.

- OEM and Private Label Capabilities

- Fast on-time Deliveries

- Friendly Customer Support

- Certified Quality System CSA B51-09 SAI GLOBAL

- UL Listing

- CSA Listing

140Specification